Maintenance

In an environment increasingly marked by fierce competition and dynamic market development, companies are coming under enormous pressure. This makes it all the more critical to have machines that perform reliably and are fully functional at all times. Companies are thus faced with the daily challenge of minimizing downtime wherever possible.

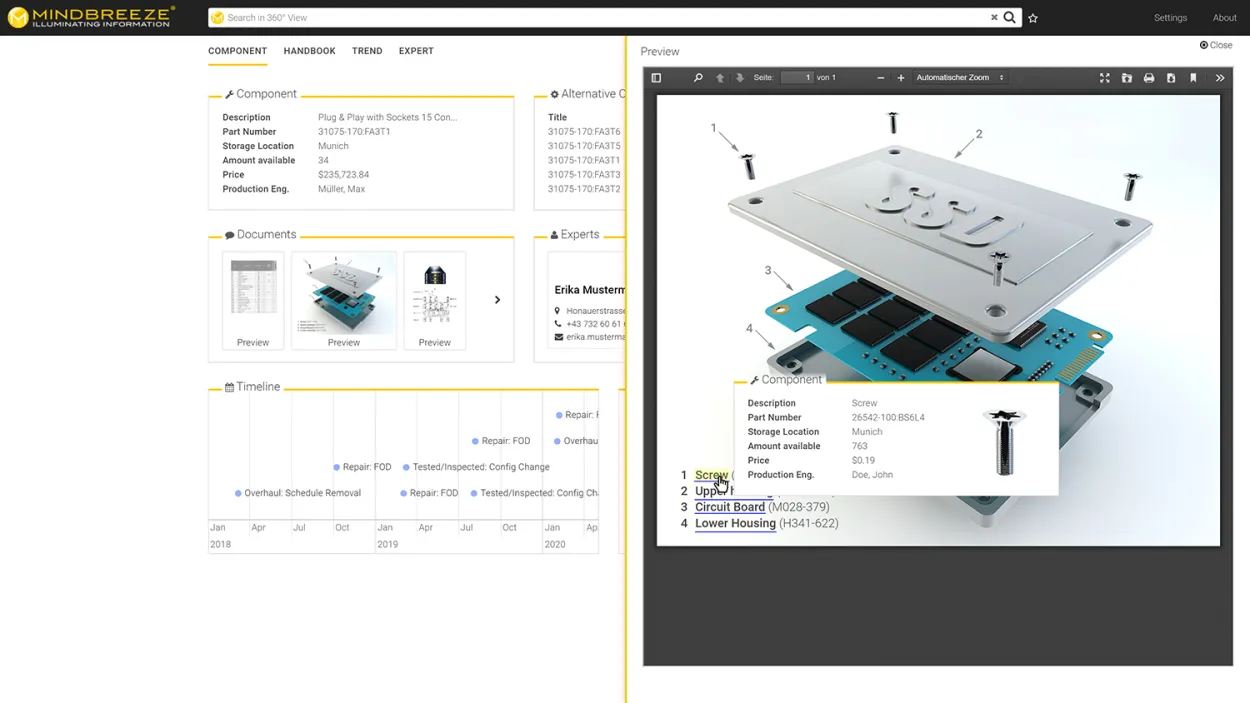

By evaluating certain data relating to the machine, correlations between the individual components and processes can be recognized. The objective here is not merely to collect data arbitrarily, but rather to analyze, interpret, and leverage historical and real-time data in a way that is systematic and precisely targeted. This calls for AI technologies capable of generating a so-called 360 - degree view of a given component or machine, graphically presented on a dashboard. This means, for instance, that beyond simply identifying the top tasks involved in maintenance, these tasks can be linked to spare parts lists, maintenance manuals, and orders.

Mindbreeze InSpire for maintenance enables companies to:

- Identify the optimal time for maintenance

- Safeguard the production capability

- Boost productivity

- Maximize profitability

- Optimize capacity utilization and machine performance

"Mindbreeze is helping us move one step further into the future of digitalization so we can better provide our employees with all the information they need. Now, for instance, we can leverage the expertise of our researchers and developers faster and in a more targeted way, which enables us to offer our customers more and more new and innovative products and services."

Corporate Innovation Manager

Lufthansa Group

Download Case Study

Fill in the form and you’ll receive an e-mail with a link to download the case study.

![[Case Study] Keep Planes Flying - How centralized data helps airlines fly](/sites/default/files/styles/380px/public/2023-07/%5BCase-Study%5D-Keep-Planes-Flying---How-centralized-data-helps-airlines-fly-1.jpg.webp?itok=liBY6z94)