How many components is an aircraft made of?

Digital twins and insight engines in the context of aircraft maintenance

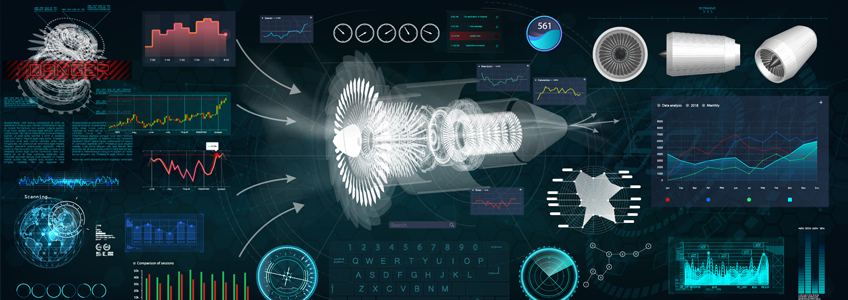

You’re probably familiar with the feeling of sitting in an airplane, waiting for take-off, and just letting your mind wander. A glance through the cabin reveals countless welding seams, screws, or – if you look out of the window – the turbine, the wings and their flaps, and so much more.

A Boeing 747-8 is composed of some six million components, and it takes about four months to build an aircraft from its individual parts.

Considering the amount of work and the purchase price, it’s perfectly logical to see why every malfunction generates enormous costs. The primary goal is thus to keep the time an aircraft spends on the ground as short as possible. Those in charge of the aircraft handle all the tasks that have to be completed after landing or before the next take-off with impeccable coordination. On top of this, there are the routine maintenance inspections.

This is where digital twins are particularly valuable, providing a digital image of everything from the reading light to the turbine and its components. By using methods of artificial intelligence for state-of-the-art knowledge management, all critical information from the various data sources is accessible at the touch of a button.

How this works in practice is explained in our case study “Efficient knowledge management in the aviation industry.”

Are you interested in putting this application into practice in your company, too? We look forward to hearing from you.

Latest Blogs

Inside Insight: How Journeys and Touchpoints Make Enterprise Search Effortless with Mindbreeze Insight Workplace

Picture this: you’re preparing for a high-stakes client meeting.

The Future of Enterprise AI Depends on Smarter RAG Solutions

Today’s enterprise leaders ask how to make AI meaningful, responsible, and scalable. One architectural approach stands out as organizations look beyond isolated proof-of-concepts and begin embedding AI into workflows: Retrieval-Augmented Generation (RAG).